Relocation Of College Print Shop Equipment

Scope Of Work:

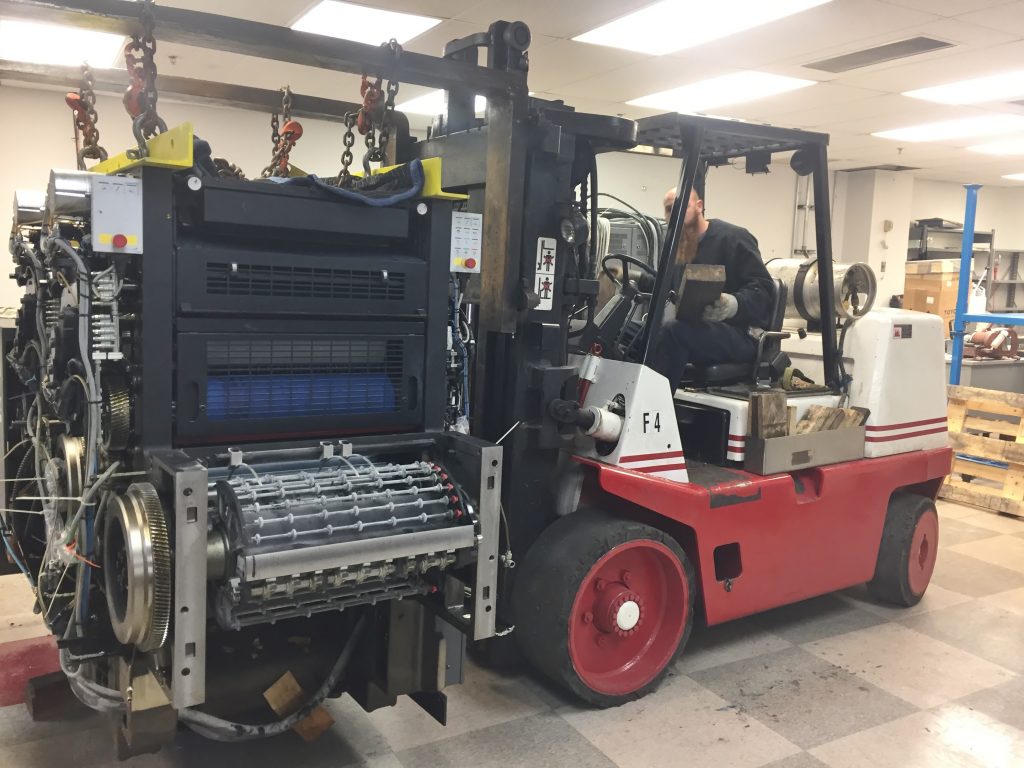

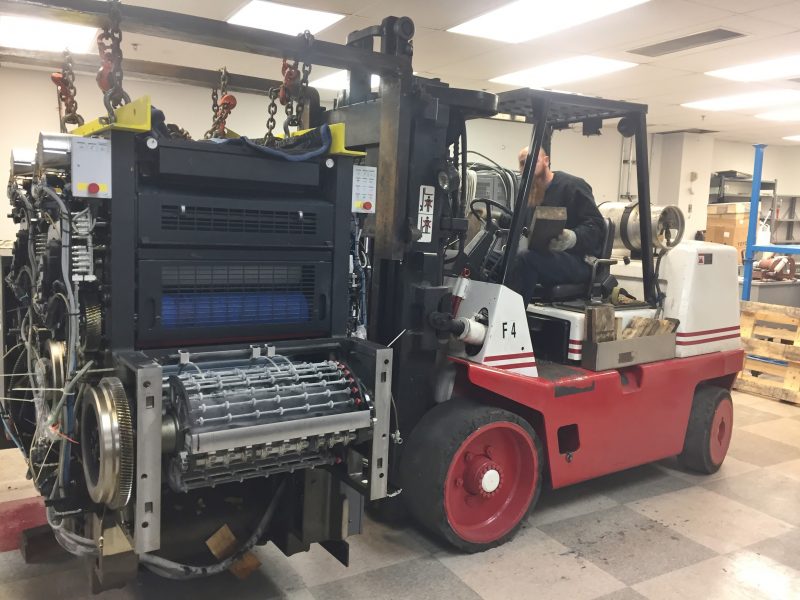

Relocate printing equipment from college print shop from an upper floor to basement area of building. Included in this relocation was a Heidelberg SM52 4-color press that was separated into sections weighing 10,500 lb. and 7,500 lb. respectively. The sections were lowered into the basement through a hatch area. However, this hatch area or opening to the basement was ‘dimensionally’ shorter than the length of the press sections.

Additionally, there was no overhead lift beam or structural rigging point above the opening. Nor was there adequate room around the opening to get close to it with a lift truck.

Project:

- Match-mark, dismantle, relocate and reassemble multiple pieces print shop equipment

- Equipment included Heidelberg SM52 4-color Press

Unique Challenges:

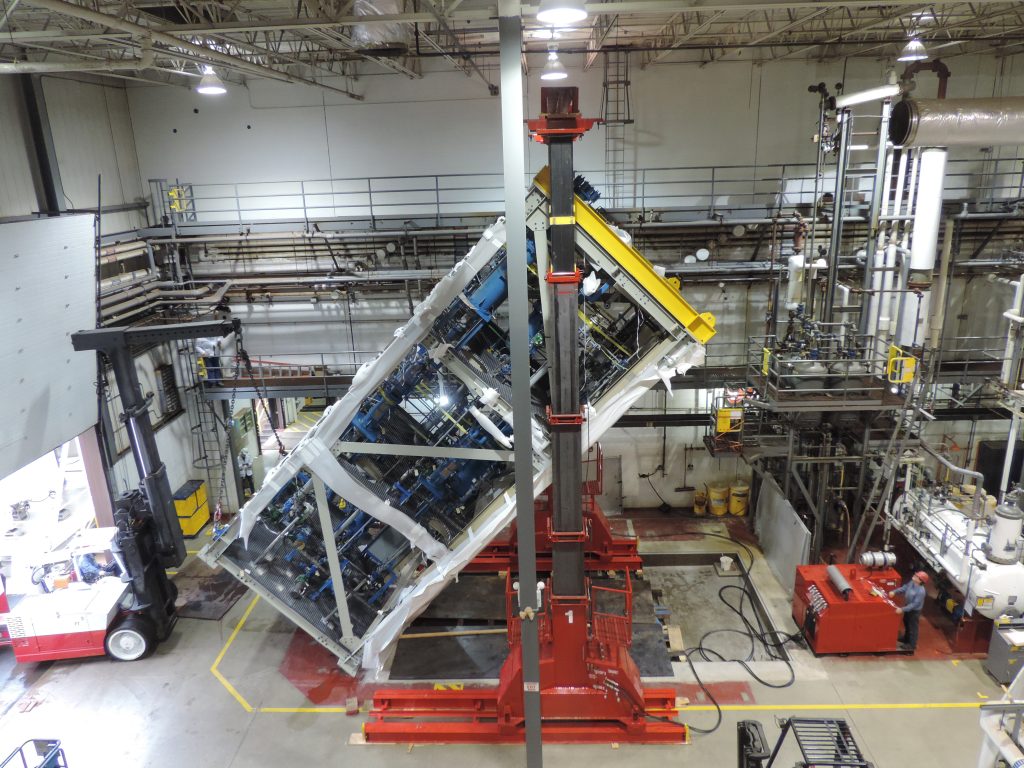

The dismantled press sections were 105 in. long. That exceeded the length of the 97 in. long hatch opening through which these press sections needed to be lowered. Additionally, there was insufficient floor load capacity. There was also lack of clearance around the hatch opening preventing the use of gantries or appropriately sized lift trucks. Our approach consisted of getting as close as possible with a lift truck equipped with a tubular steel boom. We sleeved a steel beam inside the boom, spanned the opening and fastened the opposite end to the wall.

Two (2) 5 ton capacity chain hoists on trollies were mounted on the beam to rig the load. Furthermore, the section(s) were tilted approximately 25° to reduce the overall length so they could be lowered through the opening with approximately 1.5 in. clearance. A scissors lift in the basement was used as a receiving platform by elevating and blocking/supporting the platform.