Share

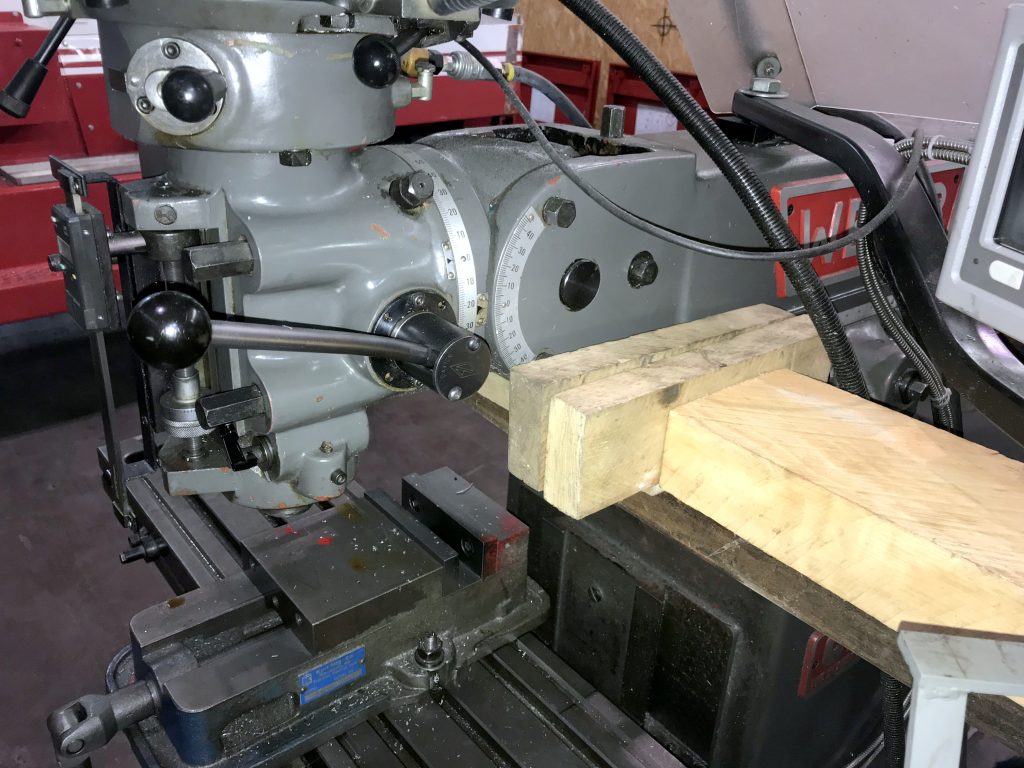

Simple Steps to Move a Vertical Milling Machine

Proper Lifting and Moving Techniques for Vertical Milling Machines

“You mauled that milling machine! You mauled that milling machine!”

This is what Tim Cromwell, Manager of Sales & Acquisitions of A&A Machinery Sales heard in the aftermath, as two unqualified operators moved a Bridgeport Mill at an auction. Due to the Mill not being properly secured, it fell off the loading dock as it was being loaded onto a truck.

The buyer had his forks under the mill’s base with no straps. When he drove off the loading dock onto the flatbed, the trailer dropped a few inches, enough to get the vertical mill to tip and fall off the trailer on to the ground.

If you have visited many auctions or spent much time in machine shops, you’ve seen it. A vertical milling machine lying on its side, oil spilling on the floor, and broken handles.

There are many ways to move Vertical Milling Machines but only a few ways to do it correctly and safely.

As a rigging and machinery moving contractor who has seen its fair share of other companies with unqualified operators damage machines, we would recommend hiring someone with the experience and correct equipment such as A&A Machinery Moving to move your machines. Experienced companies have an understanding of how to move these machines while minimizing potential damage or worse.

If you plan to risk it move the Vertical Milling Machine yourself, use these simple steps below to move your vertical milling machine safely and securely.

Pick up the Vertical Milling Machine under the Ram

This can be done from the sides, the front, or the back of the Vertical Milling Machine.

Loading from either side (Recommended)

- Lift your forks and spread them to just fit around the column.

- Move in until the forks have extended past the Ram.

- Place rubber pads or wood between the forks and the ram. This creates friction to reduce the chance of sliding.

- Put oak or solid wood timbers between mill and the back of the forks. This will stop the mill from sliding back towards the forklift.

- Run a cargo strap around the mill and attach to the mast. This will stop the mill from sliding off of the forks.

Loading from the front or the back

- Lift your forks and spread them to just fit around the column.

- Move in until the forks are to the end of the Ram (Forks will be parallel with the Ram).

- Place 4×6 oak or solid wood timbers on top of the forks and under the Ram. Make sure to keep the timbers close to the column.

- Put oak or solid wood timbers between these 4×6 timbers and the back of the forks. This will stop the mill from sliding back towards the forklift.

- Run a cargo strap around the mill and attach to the mast. This will stop the mill from sliding off of the forks.

You invested in purchasing that Vertical Milling Machine. If you don’t have the right equipment to move the Mill correctly and safely, don’t skip out on hiring an experienced rigger or machine mover. Avoid risking potential damage to the machine by moving it yourself without the knowledge and right equipment. Hire an experienced contractor with the right equipment to assist such as A&A Machinery Moving.

Whether you’re moving one machine or an entire plant, our team here at A&A Machinery understands the correct and safe way to move any machine you may have. Regardless of weight or size, we have the right rigging equipment and know-how to move it, relocate it, or remove it.

For more information, you can request a quote here.

Published May 28th, 2019

Simple Steps to Move a Vertical Milling Machine

Proper Lifting and Moving Techniques for Vertical Milling Machines

“You mauled that milling machine! You mauled that milling machine!”

This is what Tim Cromwell, Manager of Sales & Acquisitions of A&A Machinery Sales heard in the aftermath, as two unqualified operators moved a Bridgeport Mill at an auction. Due to the Mill not being properly secured, it fell off the loading dock as it was being loaded onto a truck.

The buyer had his forks under the mill’s base with no straps. When he drove off the loading dock onto the flatbed, the trailer dropped a few inches, enough to get the vertical mill to tip and fall off the trailer on to the ground.

If you have visited many auctions or spent much time in machine shops, you’ve seen it. A vertical milling machine lying on its side, oil spilling on the floor, and broken handles.

There are many ways to move Vertical Milling Machines but only a few ways to do it correctly and safely.

As a rigging and machinery moving contractor who has seen its fair share of other companies with unqualified operators damage machines, we would recommend hiring someone with the experience and correct equipment such as A&A Machinery Moving to move your machines. Experienced companies have an understanding of how to move these machines while minimizing potential damage or worse.

If you plan to risk it move the Vertical Milling Machine yourself, use these simple steps below to move your vertical milling machine safely and securely.

Pick up the Vertical Milling Machine under the Ram

This can be done from the sides, the front, or the back of the Vertical Milling Machine.

Loading from either side (Recommended)

- Lift your forks and spread them to just fit around the column.

- Move in until the forks have extended past the Ram.

- Place rubber pads or wood between the forks and the ram. This creates friction to reduce the chance of sliding.

- Put oak or solid wood timbers between mill and the back of the forks. This will stop the mill from sliding back towards the forklift.

- Run a cargo strap around the mill and attach to the mast. This will stop the mill from sliding off of the forks.

Loading from the front or the back

- Lift your forks and spread them to just fit around the column.

- Move in until the forks are to the end of the Ram (Forks will be parallel with the Ram).

- Place 4×6 oak or solid wood timbers on top of the forks and under the Ram. Make sure to keep the timbers close to the column.

- Put oak or solid wood timbers between these 4×6 timbers and the back of the forks. This will stop the mill from sliding back towards the forklift.

- Run a cargo strap around the mill and attach to the mast. This will stop the mill from sliding off of the forks.

You invested in purchasing that Vertical Milling Machine. If you don’t have the right equipment to move the Mill correctly and safely, don’t skip out on hiring an experienced rigger or machine mover. Avoid risking potential damage to the machine by moving it yourself without the knowledge and right equipment. Hire an experienced contractor with the right equipment to assist such as A&A Machinery Moving.

Whether you’re moving one machine or an entire plant, our team here at A&A Machinery understands the correct and safe way to move any machine you may have. Regardless of weight or size, we have the right rigging equipment and know-how to move it, relocate it, or remove it.

For more information, you can request a quote here.

Published May 28th, 2019